Why do we need SMART supplier self-assessment questionnaires?

by Russ Brown and Liudmila Chambers,

An increasing number of country and regional regulations require companies to conduct human rights and environmental due diligence in their supply chains, which often involves supplier risk assessment and risk mitigation. Given the cost and complexities associated with audits, supplier self-assessment questionnaires (SAQs) offer a logical first step for many companies.

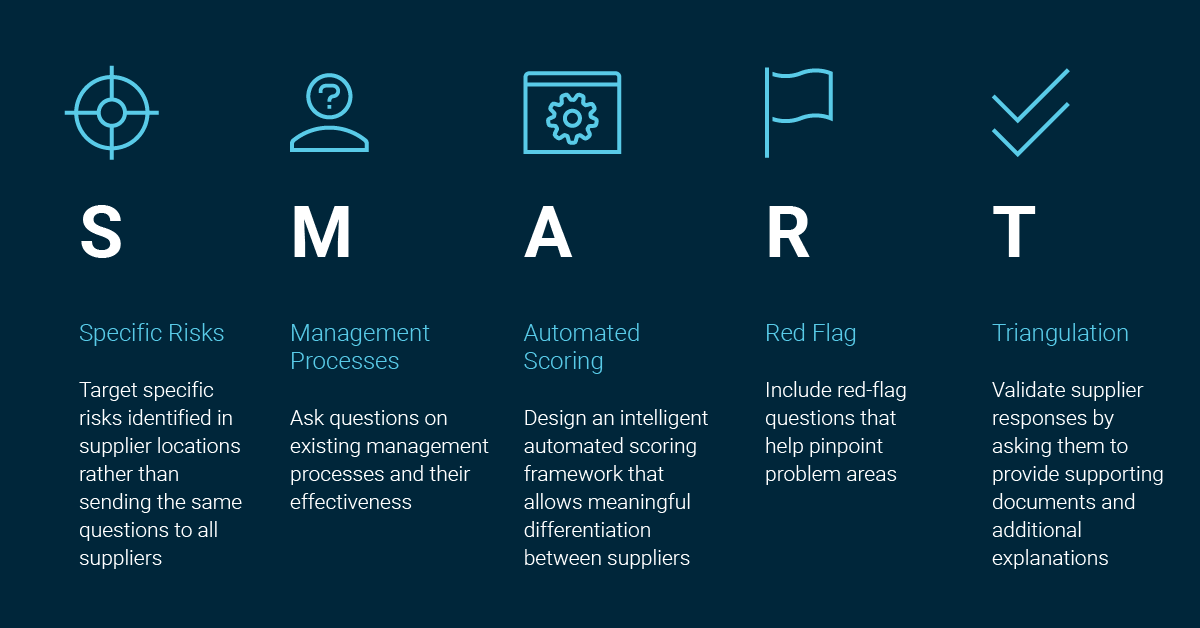

It is tempting – and certainly simpler – to demonstrate compliance by sending the same self-assessment questionnaire to all suppliers without differentiating by location or industry. But this seemingly logical strategy is fraught with challenges, including ingrained biases, inflexibility and respondent fatigue. Adopting a more flexible, modular approach and targeting specific risk issues through SMART SAQ is a more effective solution. This insight focuses on two key challenges of traditional SAQs and how these are overcome through the SMART SAQ solution.

Challenge #1. Traditional supplier SAQs are too long and produce limited insights for buyers

Many, if not most, supplier SAQs include more than a hundred questions, often targeting a variety of environmental, social and governance (ESG) issues. This problem is compounded by the fact that suppliers often receive uncoordinated requests from multiple companies or buyers. Unsurprisingly, this typically leads to ‘questionnaire fatigue’ and low response rates. Suppliers either fail to complete questionnaires in their entirety or only provide answers to selected questions – typically those that are easiest to respond to. As a result, buyers do not receive a full picture of the risk management practices in their supply chain.

Using the Pareto 80/20 principle as a lens, one can expect that 20% of supplier responses will predict 80% of the issues within risk management systems. What this means in practice is that out of 100 questions in a traditional SAQ, only around 20 will help to evaluate the maturity of a supplier’s approach to risk management. The other 80 questions collect contextual information that often goes unreviewed, thus wasting the supplier’s time with only limited benefits to the buyer.

Solution #1. SMART SAQs reduce the length of supplier self-assessment questionnaires by adopting a modular approach

SMART SAQs ask relevant questions by utilising our broad suite of proprietary risk indices to pinpoint supplier exposure to specific ESG risks. For example, if a supplier has a relatively high exposure to forced labour risks (i.e., a high or extreme risk score on our Forced Labour Index), questions will be asked to target this specific risk issue. By contrast, if a supplier has a relatively low exposure to occupational health and safety (OHS) risks given its country of operation and industry, no additional OHS questions will be asked.

Suppliers receive a core SAQ module, with questions covering ESG policies, risk assessments, actions, performance tracking and communication, remedy and grievance mechanisms. Adopting the SMART logic means that suppliers with limited risk exposure will only receive this smaller set of questions. Suppliers with a high-risk of exposure receive a larger set of questions, tailored to their specific exposure profile.

Challenge #2. Traditional supplier SAQs do not differentiate between supplier profiles to enable effective supply chain management strategies

Self-assessment questionnaires are impacted by social desirability bias, wherein respondents opt for answers that make them feel better about themselves, or for answers they feel are better aligned with societal expectations. For this reason, binary ‘Yes/No’ questionnaires often struggle to produce differentiation in respondent profiles. This is often the case with traditional SAQs, where the majority of suppliers emerge with good or excellent SAQ scores.

Another consequence of traditional SAQ questionnaire design is that suppliers with limited exposure to ESG risks will often perform worse on SAQs than suppliers with higher risk exposure. Although it is possible to imagine a scenario where a supplier in a country with a high-risk profile is more advanced in its risk management processes than a supplier in a lower risk country, in most cases this counterintuitive result stems from sending the wrong questions to the wrong suppliers, and applying the wrong scoring framework to their responses. For example, a standalone child labour policy may be relevant for a cocoa supplier in Ghana but not for a professional services firm in the UK. Penalising the latter for indicating that it doesn’t have a standalone child labour policy would fail to produce an effective supplier management strategy.

Solution #2. SMART SAQs improve supplier differentiation and reduce social desirability bias by providing granular response options

SMART SAQs move away from ‘Yes/No’ answers by offering suppliers a menu of response options based on their relative risk exposure, as identified by our proprietary risk indices. A SMART question on forced labour, for example, could look as follows:

What checks are in place to identify actual or potential situations of forced labour in your operations? Select all that apply and provide supporting evidence.

- No legal documents (such as travel documents and identity cards) are collected from employees throughout the hiring process other than to confirm identity at the time of hiring

- Workers are not charged or required to make a deposit for tools, personal protective equipment or anything they need to do their job

- Workers are free to leave the place of work or living quarters when not working and their freedom of movement is not restricted in any way

- Workers are free to leave their employment after reasonable notice

- Workers are not coerced to work excessive hours or in unreasonable (e.g. unsafe or unhealthy) conditions by the use of threat or force

- None of the above

The number of checks in place will depend on supplier maturity. Social desirability bias may still result in a supplier selecting some of these answers, but there is a greater chance that only the most advanced suppliers will select all five answer options. This could be accounted for in a scoring framework that only allows for a maximum score of 10 when all five answers are selected. Respondents that fail to select all five answers would receive one point per answer option. The resulting differentiation would allow for the better targeting of suppliers through effective supply chain management strategies.

A better solution

We have extensive experience in helping businesses design and implement SMART SAQ solutions, either in partnership with other service providers or by integrating into our clients’ supplier management systems. The feedback we have received shows that the modular, supplier-specific approach undertaken by SMART SAQs offers a more effective solution to supplier risk assessment and risk mitigation.